Corp Coach Svc

Organotypic Cell System Svc

Our Management Operation Coaches are versed in designing, manufacturing, and distributing lab-on-chip technologies.

Innovative Platform Technology Merging Lab-on-a-Chip with 3D Tissues

Create platforms that combines microfluidic lab-on-a-chip technology with physiologically relevant 3D tissues (e.g. spheroids, gel entrapment, cell aggregates, tissue slices) to enable formation and long-term culture of multicellular organoids for lead-compound development and drug screening.

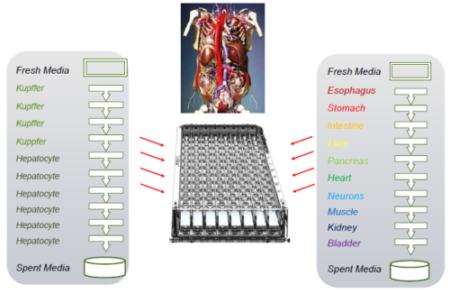

Sequentially Linked System of Aligned Cell Organoids

Connect up to 10 cell-compartments for compartment-to-compartment signalling (cell communication). Seed in static conditions to allow each organoid to be supported with cell-specific-nutrients. Then, when ready, connect the compartments to create a fluid-linked and cell-communication system.

Microsizing 3D Drug-Cell Interactions

Micro sizing drug-cell interactions significantly reduces cost of experiments while also increasing productivity as it enables more experiments to be done on the same platform at the same time.

Cost Effective Approach to High-Throughput Drug Screening

A microfluidic platform provides a cost-effective approach to applications including high-throughput drug screening and analysis and bioassays to assess spheroid function and morphology.

Personalized Medicine Concepts

In the area of personalized medicine, it is highly pertinent to not only predict the drug response at early time points during the therapy, but also to be able to identify the optimal drug combination for an individual patient. Within the scope of personalized medicine, this technology presents immense possibilities for testing patient-derived multicellular tumor spheroids/organoids (comprising cancer cells, stromal cells, cancer stem cells and/or immune cells) for disease/biomarker-oriented drug activity and profiling using single- and pair-wise standard/targeted drug combinations.

Data Analysis

To enable data analysis of the results from the microfluidic platform, our technology is designed to be lab agnostic. The format is a 1/2 area 96-well footprint that fits into general lab equipment. You can use traditional cell culture techniques, traditional lab equipment (readers, imagers, pipettes), and traditional assay kits. No need to buy auxiliary equipment or learn new software details.

Repeatability of MicroFluidic Platform (Polystyrene Material)

Our manufacturing process is injection molding of microfluidic chambers.The ability to injection mold and mass produce microfluidic devices is a critical product asset.

- Our injection molded material polystyrene provides additional functionality as the polystyrene chemistry replicates traditional static culture plates that are already quality controlled for A) cell culture efficacy, and B) non-specific binding of drugs/chemicals/compounds.

- Comparatively, most competitors that produce microfluidic devices employ versions of silicone during manufacturing (e.g. material base or connective tubing). Silicone is a poor cell culture surface and silicone induces non-specific binding of compounds. Silicone devices must be re-evaluated for quality control and efficacy for the unlimited hundreds-of-thousands of compounds being evaluated.